3D SCANNING SERVICE

3D Scanning Services – Precision Digital Replication & Reverse Engineering

Our 3D Scanning & Pipeline Inspection Services provide high-precision digital replication for reverse engineering, quality control, and infrastructure assessment. Using advanced 3D scanning technology, we capture detailed geometries, textures, and measurements of physical objects to create accurate digital models for manufacturing, restoration, and product development.

Additionally, our Pipeline Inspection Service ensures the integrity, safety, and efficiency of underground and industrial pipelines. We utilize cutting-edge scanning and inspection tools to detect corrosion, leaks, blockages, and structural weaknesses, helping businesses prevent failures and optimize maintenance. Whether for manufacturing, engineering, or infrastructure management, we provide precise, reliable, and data-driven solutions tailored to your needs.

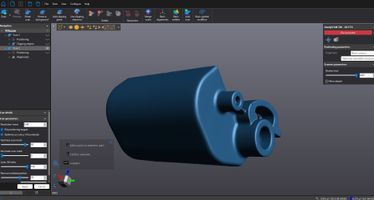

Reverse Engineering

Reverse Engineering – Recreate, Optimize & Enhance with Precision 3D Scanning

Our Reverse Engineering Service utilizes advanced 3D scanning technology to accurately analyze, recreate, and optimize existing parts and components. Whether you need to reproduce obsolete parts, improve product designs, or enhance performance, our high-precision scanning captures every detail with exceptional accuracy. Ideal for manufacturing, automotive, aerospace, and industrial applications, our reverse engineering solutions help you streamline production, reduce costs, and accelerate innovation with precise digital models and CAD-ready files.

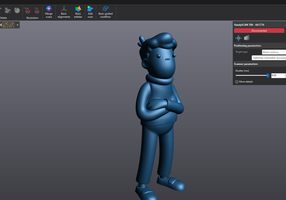

ORGANIC OBJECT 3D SCANNING

High-Precision 3D Scanning for Organic Shapes – Capture Every Natural Detail

Our Organic Object 3D Scanning service captures the intricate details, textures, and complex shapes of natural and biological objects with exceptional accuracy. Using high-resolution 3D scanning technology, we create precise digital replicas of organic forms such as plants, animals, fossils, sculptures, and anatomical structures. Ideal for applications in art, archaeology, medical research, animation, and product design, our scanning process ensures non-contact, high-fidelity data capture, preserving the integrity of delicate and irregular surfaces.

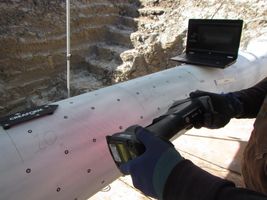

PIPELINE INSPECTION

Pipeline Inspection – Advanced Scanning for Safety, Integrity & Efficiency

Our VXelements Inspection Service utilizes Creaform’s cutting-edge 3D scanning and metrology software to deliver high-precision inspections for quality control, reverse engineering, and pipeline assessments. With real-time 3D visualization and automated analysis, VXelements enables us to detect dimensional deviations, wear, corrosion, and defects with exceptional accuracy. This non-destructive testing (NDT) method ensures fast, reliable, and comprehensive data acquisition, making it ideal for manufacturing, aerospace, automotive, and industrial applications. Whether verifying complex geometries or ensuring regulatory compliance, our VXelements-based inspection services provide precise reports and actionable insights to optimize your operations.