3D PRINTING

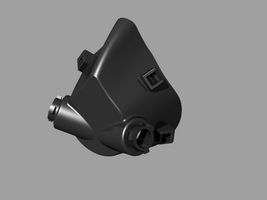

At Qrint, we offer cutting-edge 3D printing services in FDM, SLS, SLA designed to meet your prototyping, production, and custom manufacturing needs. Whether you require large-scale parts, high-volume production, or precision detailing, we have the expertise and technology to deliver.

Precision in Every Dimension.

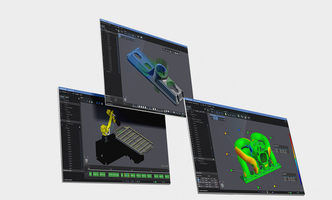

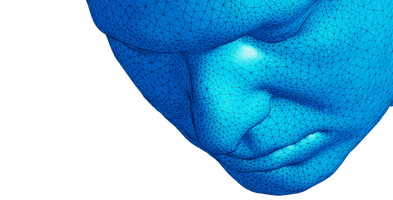

Professional 3D Modeling Services

Comprehensive 3D Printing Repair & Training Services

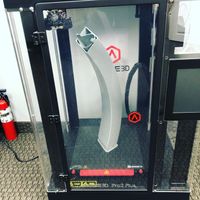

Expert 3D Printer Repair & Training – Serving Schools, Colleges, Businesses Nationwide

We offer professional 3D printing repair services, both on-site and off-site, to ensure your printers operate at peak performance. Whether you’re dealing with hardware malfunctions, calibration issues, or failed prints, our expert technicians provide fast, reliable repairs and maintenance for all types of 3D printers.

For businesses and institutions, we also offer customized off-site training classes, helping you optimize your printer settings and workflows for specialized projects. Our team provides tailored solutions to schools, colleges, universities, and companies, ensuring their 3D printing labs run smoothly.

With technicians available across Canada, we’re ready to assist with repairs, upgrades, and troubleshooting—wherever you need us. Whether you’re an educational institution, a business, or an individual user, we’ve got you covered with expert 3D printing support and repair services.

3D PRINTER FILAMENT IN 2.85

Case Studies

Molson Case Study

Case Study: Qrint Studio's 3D Printing Solution for JJDown at Molson Brewery

Client: JJDown

Industry: Brewery Packaging & Manufacturing

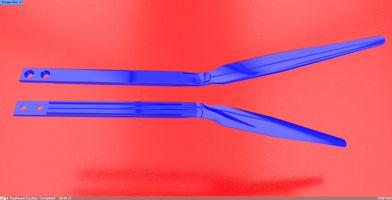

Challenge: Molson Brewery operates an advanced packaging line where plastic guide fingers assist in opening boxes, allowing the automated production line to place beer bottles inside. Over time, these guide fingers wore out due to continuous use. However, the original manufacturer of the packaging machine had discontinued the supply of these parts due to the machine's older model, leaving JJDown with a critical operational challenge.

Adding to the complexity, these guide fingers had a unique property known as "position memory." Regardless of how they were bent, they would always return to a precise 30-degree angle, ensuring accurate and efficient bottle placement within the packaging process. Without these parts, production efficiency and bottle placement accuracy were significantly impacted.

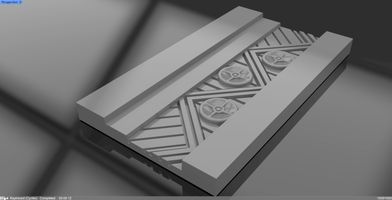

Solution: Qrint Studio collaborated with JJDown to develop a modern replacement solution using advanced 3D scanning, modeling, and additive manufacturing technologies. The process involved:

Reverse Engineering:

Qrint Studio utilized 3D scanning technology to capture the exact dimensions and properties of the worn-out guide fingers.

Material Selection:

After analyzing the requirements, Qrint selected Polypropylene, a durable and flexible material with excellent shape retention properties, ensuring the new guide fingers would maintain their 30-degree bend memory.

3D Modeling & Printing:

The team created a precise digital model of the component and optimized it for strength and flexibility. Using high-resolution 3D printing, Qrint produced a batch of replacement fingers tailored for Molson Brewery's packaging line.

Testing & Implementation:

The newly fabricated guide fingers were installed and tested in the production environment. They performed flawlessly, restoring the efficiency of the packaging line without requiring modifications to the existing machinery.

Results:

Restored Production Efficiency:

The newly produced guide fingers seamlessly integrated into the existing machinery, ensuring continued smooth operations.

Cost-Effective Solution:

Instead of replacing the entire packaging system, JJDown was able to extend the life of the machine with a custom 3D-printed part at a fraction of the cost.

Enhanced Durability & Performance:

The Polypropylene material provided durability and shape retention properties that met the production demands.

Sustainable Manufacturing:

By utilizing 3D printing, Qrint Studio helped reduce waste and reliance on traditional supply chains.

Conclusion: Qrint Studio's innovative approach to 3D printing and materials engineering provided JJDown and Molson Brewery with a practical, cost-effective, and sustainable solution. This case exemplifies how modern additive manufacturing can extend the life of industrial machinery and reduce downtime, ensuring seamless production operations.

Qrint Studio

We are a leading 3D Studio specializing in cutting-edge 3D technology services, including scanning, modeling, and high-quality printing filaments. With over 20 years of combined experience in engineering and 3D visualization, our team brings deep expertise in Industrial and Organic CAD design. Our strong foundation in Math, Physics, Chemistry, IT, and Electronics enables us to deliver precise, innovative, and reliable solutions for a wide range of industries. Whether you need reverse engineering, product development, or custom 3D designs, we turn your ideas into reality with accuracy and efficiency.

Our Mission

Our mission is to empower innovation through advanced 3D technology. We strive to provide high-precision 3D scanning, modeling, and printing solutions that help businesses and creators bring their ideas to life. With a strong foundation in engineering, CAD design, and cutting-edge technology, we are committed to delivering accurate, reliable, and efficient services tailored to our clients' needs. Our goal is to drive progress across industries by making 3D technology accessible, precise, and impactful.

Delivery

All orders are delivered within 7 days, ensuring you receive your items quickly and in perfect condition. Track your order every step of the way and experience hassle-free shipping across the country.

Location

Located at 65 Densley Ave, Design District, North York, Toronto, ON, Qrint Studio is at the heart of innovation and creativity. Our studio specializes in high-quality 3D printing, prototyping, and custom fabrication, catering to designers, businesses, and hobbyists alike. Easily accessible in Toronto’s renowned Design District, we provide expert solutions to bring your ideas to life. Stop by to discuss your project, explore our cutting-edge technology, or pick up your custom prints.

QRINT STUDIO

3D PRINTING - 3D SCANNING - 3D MODELING

LARGE SCALE 3D PRINTING

Small or Large Scale Production

"Bring your design to reality today